|

|

1

|

|

2

|

|

3

|

Click Add.

|

|

4

|

Click

|

|

5

|

|

6

|

Click

|

|

1

|

|

2

|

|

3

|

|

4

|

Browse to the model’s Application Libraries folder and double-click the file lumped_li_battery_capacity_loss_parameters.txt.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

In the Model Builder window, under Component 1 (comp1)>Lumped Battery (lb) click Cell Equilibrium Potential 1.

|

|

2

|

|

3

|

|

4

|

|

5

|

Browse to the model’s Application Libraries folder and double-click the file lumped_li_battery_capacity_loss_E_OCP_data.txt.

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

Locate the Concentration Overpotential section. Select the Include concentration overpotential check box.

|

|

7

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Select the Voltage check box.

|

|

6

|

|

7

|

|

8

|

|

9

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

Click

|

|

5

|

Click

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

|

3

|

Locate the Data section. From the Dataset list, choose Study 1: Calendar life/Parametric Solutions 1 (sol2).

|

|

1

|

|

2

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

9

|

|

10

|

|

11

|

|

1

|

|

2

|

|

3

|

Select the Current check box.

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

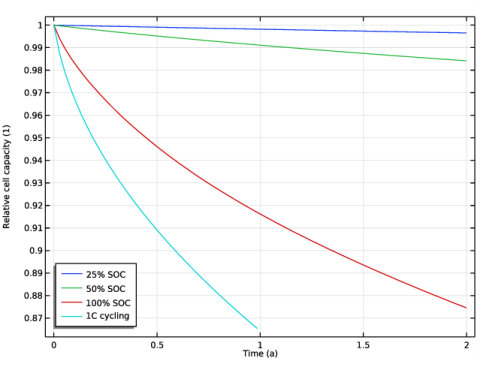

In the Model Builder window, under Results>Relative Cell Capacity right-click Global 1 and choose Duplicate.

|

|

2

|

|

3

|

|

4

|

Click to expand the Legends section. In the table, enter the following settings:

|

|

1

|

|

2

|