|

|

1

|

|

2

|

|

3

|

Click Add.

|

|

4

|

|

5

|

Click Add.

|

|

6

|

Click

|

|

7

|

In the Select Study tree, select Preset Studies for Selected Physics Interfaces>Lithium-Ion Battery>Time Dependent with Initialization.

|

|

8

|

Click

|

|

1

|

|

2

|

|

3

|

|

4

|

Browse to the model’s Application Libraries folder and double-click the file internal_short_circuit_parameters.txt.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Click to expand the Layers section. In the table, enter the following settings:

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

Locate the Coordinates section. In the table, enter the following settings:

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

Locate the Coordinates section. In the table, enter the following settings:

|

|

5

|

|

1

|

|

2

|

|

1

|

|

2

|

|

1

|

|

2

|

|

1

|

|

2

|

|

1

|

|

2

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

In the Add dialog box, in the Selections to add list, choose Negative CC, Positive CC, and Penetrating Filament.

|

|

5

|

Click OK.

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

In the Add dialog box, in the Selections to add list, choose Negative Terminal and Positive Terminal.

|

|

6

|

Click OK.

|

|

1

|

|

2

|

|

3

|

In the tree, select Built-in>Aluminum.

|

|

4

|

|

5

|

In the tree, select Built-in>Copper.

|

|

6

|

|

7

|

In the tree, select Battery>Electrodes>NMC 111 Electrode, LiNi0.33Mn0.33Co0.33O2 (Positive, Li-ion Battery).

|

|

8

|

|

9

|

|

10

|

|

11

|

|

12

|

|

13

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

In the Model Builder window, click NMC 111 Electrode, LiNi0.33Mn0.33Co0.33O2 (Positive, Li-ion Battery) (mat3).

|

|

2

|

|

3

|

|

1

|

In the Model Builder window, click Graphite Electrode, LixC6 MCMB (Negative, Li-ion Battery) (mat4).

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

In the Model Builder window, under Component 1 (comp1) right-click Lithium-Ion Battery (liion) and choose Porous Electrode.

|

|

2

|

In the Settings window for Porous Electrode, type Porous Electrode 1 (Negative) in the Label text field.

|

|

3

|

|

4

|

Locate the Electrolyte Properties section. From the Electrolyte material list, choose LiPF6 in 3:7 EC:EMC (Liquid electrolyte, Li-ion Battery) (mat5).

|

|

5

|

Locate the Electrode Properties section. From the Electrode material list, choose Graphite Electrode, LixC6 MCMB (Negative, Li-ion Battery) (mat4).

|

|

6

|

|

7

|

|

1

|

In the Model Builder window, expand the Porous Electrode 1 (Negative) node, then click Particle Intercalation 1.

|

|

2

|

|

3

|

From the Particle material list, choose Graphite Electrode, LixC6 MCMB (Negative, Li-ion Battery) (mat4).

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

In the Settings window for Porous Electrode, type Porous Electrode 2 (Positive) in the Label text field.

|

|

3

|

|

4

|

Locate the Electrode Properties section. From the Electrode material list, choose NMC 111 Electrode, LiNi0.33Mn0.33Co0.33O2 (Positive, Li-ion Battery) (mat3).

|

|

5

|

|

6

|

|

1

|

In the Model Builder window, expand the Porous Electrode 2 (Positive) node, then click Particle Intercalation 1.

|

|

2

|

|

3

|

From the Particle material list, choose NMC 111 Electrode, LiNi0.33Mn0.33Co0.33O2 (Positive, Li-ion Battery) (mat3).

|

|

4

|

|

1

|

|

2

|

|

3

|

From the Material list, choose NMC 111 Electrode, LiNi0.33Mn0.33Co0.33O2 (Positive, Li-ion Battery) (mat3).

|

|

4

|

|

1

|

|

2

|

In the Settings window for Porous Electrode, type Porous Electrode 1 (Negative, Electrochemically Inactive) in the Label text field.

|

|

4

|

|

1

|

In the Model Builder window, expand the Porous Electrode 1 (Negative, Electrochemically Inactive) node, then click Porous Electrode Reaction 1.

|

|

2

|

|

3

|

|

4

|

Locate the Electrode Kinetics section. From the iloc,expr list, choose User defined. Click to expand the Heat of Reaction section. From the dEeq/dT list, choose User defined.

|

|

1

|

|

2

|

In the Settings window for Porous Electrode, type Porous Electrode 2 (Positive, Electrochemically Inactive) in the Label text field.

|

|

4

|

|

1

|

In the Model Builder window, expand the Porous Electrode 2 (Positive, Electrochemically Inactive) node, then click Porous Electrode Reaction 1.

|

|

2

|

|

3

|

|

4

|

Locate the Electrode Kinetics section. From the iloc,expr list, choose User defined. Locate the Heat of Reaction section. From the dEeq/dT list, choose User defined.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

In the Settings window for Initial Cell Charge Distribution, locate the Battery Cell Parameters section.

|

|

3

|

|

4

|

|

1

|

In the Model Builder window, expand the Initial Cell Charge Distribution 1 node, then click Negative Electrode Selection 1.

|

|

1

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

1

|

In the Model Builder window, under Component 1 (comp1)>Materials click NMC 111 Electrode, LiNi0.33Mn0.33Co0.33O2 (Positive, Li-ion Battery) (mat3).

|

|

2

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

In the Model Builder window, under Component 1 (comp1)>Materials click Lithium (Penetrating Filament) (mat6).

|

|

2

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Click OK.

|

|

6

|

|

7

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Click OK.

|

|

6

|

|

7

|

|

8

|

|

9

|

|

10

|

|

11

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

In the Settings window for Current Distribution Initialization, locate the Physics and Variables Selection section.

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

Click

|

|

5

|

|

6

|

|

7

|

|

8

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

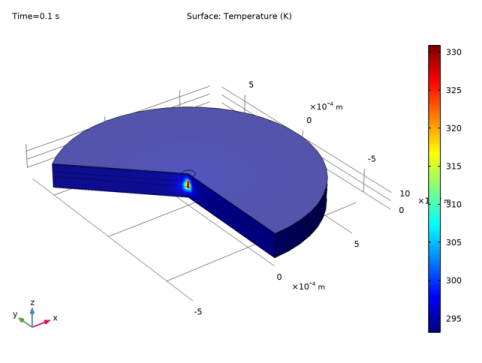

In the Settings window for 3D Plot Group, type Temperature (revolution plot) in the Label text field.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

|

1

|

|

2

|

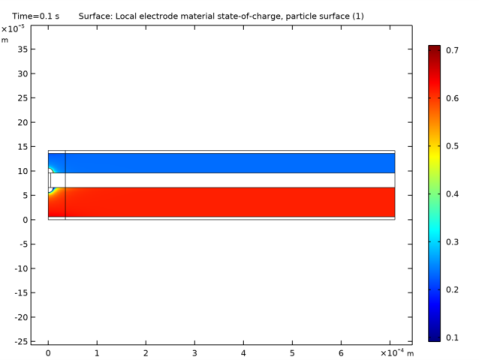

In the Settings window for Surface, click Replace Expression in the upper-right corner of the Expression section. From the menu, choose Component 1 (comp1)>Lithium-Ion Battery>Particle intercalation>liion.socloc_surface - Local electrode material state-of-charge, particle surface.

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

4

|

|

5

|