|

|

1

|

|

2

|

In the Select Physics tree, select Acoustics>Acoustic-Structure Interaction>Acoustic-Piezoelectric Interaction, Frequency Domain.

|

|

3

|

Click Add.

|

|

4

|

Click

|

|

5

|

|

6

|

Click

|

|

1

|

|

2

|

|

3

|

|

4

|

Browse to the model’s Application Libraries folder and double-click the file tonpilz_transducer_parameters.txt.

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

Click to expand the Layers section. In the table, enter the following settings:

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

Click to expand the Layers section. In the table, enter the following settings:

|

|

7

|

|

8

|

|

1

|

|

2

|

|

3

|

Click the Angles button.

|

|

4

|

|

5

|

|

1

|

|

2

|

Select the object rev1 only.

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

1

|

|

2

|

|

1

|

|

2

|

|

1

|

|

2

|

|

1

|

|

2

|

|

1

|

|

2

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

In the Add dialog box, in the Selections to add list, choose Water domain - Inner and Water domain - PML.

|

|

5

|

Click OK.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Click OK.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Click OK.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Click OK.

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

In the tree, select Built-in>Aluminum.

|

|

6

|

|

7

|

|

8

|

|

9

|

|

10

|

|

11

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

In the Model Builder window, under Component 1 (comp1) click Pressure Acoustics, Frequency Domain (acpr).

|

|

2

|

In the Settings window for Pressure Acoustics, Frequency Domain, locate the Domain Selection section.

|

|

3

|

|

4

|

Locate the Sound Pressure Level Settings section. From the Reference pressure for the sound pressure level list, choose Use reference pressure for water.

|

|

5

|

Locate the Typical Wave Speed for Perfectly Matched Layers section. In the cref text field, type 1500[m/s].

|

|

1

|

|

2

|

|

3

|

|

4

|

Locate the Exterior Field Calculation section. From the Condition in the z = z^0 plane list, choose Symmetric/Infinite sound hard boundary.

|

|

1

|

|

2

|

|

3

|

|

1

|

In the Model Builder window, under Component 1 (comp1)>Solid Mechanics (solid) click Piezoelectric Material 1.

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

Locate the Coordinate System Selection section. From the Coordinate system list, choose Rotated System 2 (sys2).

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

In the associated text field, type 1500[m/s]/f0max/6.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

1

|

In the Model Builder window, under Component 1 (comp1) right-click Definitions and choose Variables.

|

|

2

|

|

3

|

|

4

|

Browse to the model’s Application Libraries folder and double-click the file tonpilz_transducer_variables.txt.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

1

|

|

2

|

In the Settings window for Multislice, click Replace Expression in the upper-right corner of the Expression section. From the menu, choose Component 1 (comp1)>Pressure Acoustics, Frequency Domain>Pressure and sound pressure level>acpr.Lp_t - Total sound pressure level - dB.

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

Locate the Evaluation section. Find the Angles subsection. From the Restriction list, choose Manual.

|

|

5

|

|

6

|

|

7

|

|

8

|

|

9

|

|

1

|

In the Model Builder window, expand the Exterior-Field Pressure (acpr) node, then click Results>Exterior-Field Sound Pressure Level xy-plane (acpr).

|

|

2

|

In the Settings window for Polar Plot Group, type Relative polar beam sensitivity in the Label text field.

|

|

3

|

|

4

|

|

1

|

In the Model Builder window, expand the Relative polar beam sensitivity node, then click Radiation Pattern 1.

|

|

2

|

|

3

|

|

4

|

Locate the Evaluation section. Find the Angles subsection. From the Restriction list, choose Manual.

|

|

5

|

|

6

|

|

7

|

|

8

|

|

9

|

|

10

|

|

11

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

In the Settings window for Surface, click Replace Expression in the upper-right corner of the Expression section. From the menu, choose Component 1 (comp1)>Solid Mechanics>Displacement>solid.disp - Displacement magnitude - m.

|

|

1

|

|

2

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

In the associated text field, type Distance from the transducer (mm).

|

|

7

|

|

8

|

In the associated text field, type Pressure (Pa).

|

|

1

|

|

3

|

In the Settings window for Line Graph, click Replace Expression in the upper-right corner of the y-Axis Data section. From the menu, choose Component 1 (comp1)>Pressure Acoustics, Frequency Domain>Pressure and sound pressure level>p - Pressure - Pa.

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

9

|

|

10

|

|

11

|

|

13

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

In the associated text field, type Z/(\rho c).

|

|

6

|

|

1

|

|

2

|

|

4

|

|

6

|

|

1

|

|

2

|

In the Settings window for 1D Plot Group, type Transmitting Voltage Response in the Label text field.

|

|

3

|

|

4

|

|

1

|

|

2

|

|

4

|

Click

|

|

6

|

|

7

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

5

|

Click

|

|

6

|

|

7

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

9

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

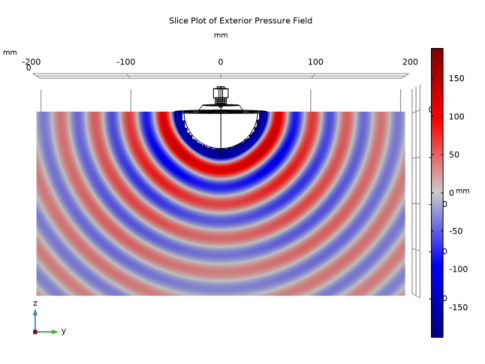

Locate the Expression section. In the Expression text field, type if(sqrt(x^2+y^2+z^2)>Rwater,pext(x,y,z),NaN).

|

|

5

|

|

6

|

|

7

|

|

8

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Locate the Expression section. In the Expression text field, type if(sqrt(x^2+y^2+z^2)>Rwater,acpr.efc1.Lp_pext,NaN).

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

3

|