|

|

•

|

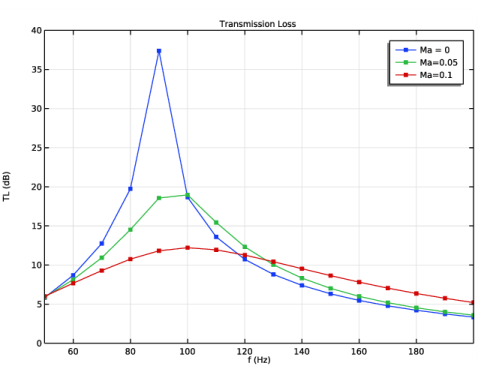

Check the Auxiliary sweep check box available in the Study Extensions section of the corresponding study and specify the desired values of the flow Mach number parameter.

|

|

•

|

|

•

|

|

1

|

|

2

|

In the Select Physics tree, select Fluid Flow>Single-Phase Flow>Turbulent Flow>Turbulent Flow, SST (spf).

|

|

3

|

Click Add.

|

|

4

|

Click

|

|

5

|

In the Select Study tree, select Preset Studies for Selected Physics Interfaces>Stationary with Initialization.

|

|

6

|

Click

|

|

1

|

|

2

|

|

3

|

|

4

|

Browse to the model’s Application Libraries folder and double-click the file helmholtz_resonator_with_flow_parameters.txt.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

Click to expand the Layers section. In the table, enter the following settings:

|

|

7

|

|

8

|

|

9

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

On the object cyl1, select Boundaries 12 and 15 only.

|

|

6

|

|

7

|

|

8

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

Click in the Graphics window and then press Ctrl+A to select all objects.

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

Select the object uni1 only.

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

On the object par1, select Domains 2, 4, 6, 8, 10, 12, 14, and 16 only.

|

|

5

|

|

1

|

|

2

|

|

3

|

|

5

|

|

1

|

|

2

|

|

3

|

|

5

|

|

1

|

|

2

|

|

3

|

In the tree, select Built-in>Air.

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

1

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

1

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

Click the Custom button.

|

|

5

|

|

6

|

|

7

|

|

8

|

|

9

|

|

1

|

|

2

|

|

3

|

|

1

|

|

3

|

|

4

|

|

1

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

In the Settings window for Boundary Layer Properties, locate the Geometric Entity Selection section.

|

|

3

|

|

4

|

Locate the Boundary Layer Properties section. In the Thickness adjustment factor text field, type 1.4.

|

|

5

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

Click

|

|

6

|

|

1

|

|

2

|

Click

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

5

|

|

1

|

|

2

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

In the Settings window for 1D Plot Group, type CFD: Turbulent Viscosity Axial in the Label text field.

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

9

|

|

1

|

|

2

|

|

3

|

|

4

|

Find the Physics interfaces in study subsection. In the table, clear the Solve check box for Study 1 - CFD.

|

|

5

|

|

6

|

|

1

|

In the Physics toolbar, click

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

Click the Custom button.

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

5

|

|

6

|

|

7

|

In the associated text field, type Dmain/15.

|

|

8

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

In the Settings window for Boundary Layer Properties, locate the Geometric Entity Selection section.

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

|

3

|

Find the Physics interfaces in study subsection. In the table, clear the Solve check boxes for Turbulent Flow, SST (spf) and Linearized Navier-Stokes, Frequency Domain (lnsf).

|

|

4

|

Find the Studies subsection. In the Select Study tree, select Preset Studies for Selected Multiphysics>Mapping.

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

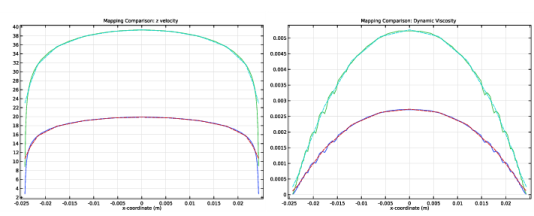

In the Settings window for 1D Plot Group, type Mapping Comparison: z velocity in the Label text field.

|

|

3

|

|

1

|

|

2

|

|

3

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

|

3

|

|

5

|

Click Replace Expression in the upper-right corner of the y-Axis Data section. From the menu, choose Component 1 (comp1)>Background Fluid Flow Coupling 1>Mapped velocity - m/s>bffc1.u_mapz - Mapped velocity, z component.

|

|

6

|

|

7

|

|

8

|

Click to expand the Coloring and Style section. Find the Line style subsection. From the Line list, choose Dashed.

|

|

9

|

|

1

|

|

2

|

|

3

|

In the Settings window for 1D Plot Group, type Mapping Comparison: Dynamic Viscosity in the Label text field.

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

In the Settings window for Line Graph, click Replace Expression in the upper-right corner of the y-Axis Data section. From the menu, choose Component 1 (comp1)>Background Fluid Flow Coupling 1>bffc1.mu_eff_map - Mapped turbulent viscosity - Pa·s.

|

|

3

|

|

1

|

In the Model Builder window, under Component 1 (comp1) right-click Definitions and choose Variables.

|

|

2

|

|

3

|

|

4

|

Browse to the model’s Application Libraries folder and double-click the file helmholtz_resonator_with_flow_variables.txt.

|

|

1

|

|

2

|

|

3

|

|

5

|

|

1

|

|

2

|

|

3

|

|

5

|

|

1

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

1

|

|

3

|

In the Settings window for Background Acoustic Fields, locate the Background Acoustic Fields section.

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

In the Show More Options dialog box, in the tree, select the check box for the node Physics>Stabilization.

|

|

9

|

Click OK.

|

|

10

|

|

11

|

In the Settings window for Linearized Navier-Stokes, Frequency Domain, click to expand the Stabilization section.

|

|

12

|

|

1

|

|

2

|

|

3

|

Find the Physics interfaces in study subsection. In the table, clear the Solve check box for Turbulent Flow, SST (spf).

|

|

4

|

Find the Multiphysics couplings in study subsection. In the table, clear the Solve check box for Background Fluid Flow Coupling 1 (bffc1).

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

|

3

|

Click to expand the Values of Dependent Variables section. Find the Values of variables not solved for subsection. From the Settings list, choose User controlled.

|

|

4

|

|

5

|

|

6

|

|

7

|

Click to expand the Mesh Selection section. Add an auxiliary sweep to solve for the two Mach numbers.

|

|

8

|

|

9

|

Click

|

|

11

|

|

12

|

|

13

|

|

14

|

|

15

|

|

16

|

|

1

|

|

2

|

|

3

|

In the Model Builder window, expand the Study 3 - Acoustics, Ma = 0.05 and Ma = 0.1>Solver Configurations>Solution 4 (sol4)>Stationary Solver 1 node.

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

Find the Physics interfaces in study subsection. In the table, clear the Solve check boxes for Study 1 - CFD, Study 2 - Mapping, and Study 3 - Acoustics, Ma = 0.05 and Ma = 0.1.

|

|

4

|

|

5

|

|

6

|

|

1

|

Right-click Component 1 (comp1)>Pressure Acoustics, Frequency Domain (acpr) and choose Narrow Region Acoustics.

|

|

3

|

|

4

|

|

5

|

|

1

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

Find the Physics interfaces in study subsection. In the table, clear the Solve check boxes for Turbulent Flow, SST (spf) and Linearized Navier-Stokes, Frequency Domain (lnsf).

|

|

4

|

Find the Multiphysics couplings in study subsection. In the table, clear the Solve check box for Background Fluid Flow Coupling 1 (bffc1).

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

|

3

|

Locate the Data section. From the Dataset list, choose Study 4 - Acoustics, Ma = 0/Solution 5 (sol5).

|

|

4

|

|

5

|

|

7

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

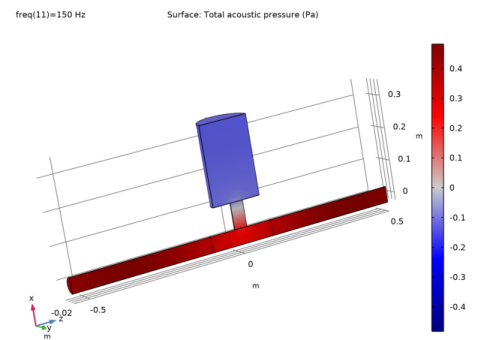

In the Settings window for 3D Plot Group, type Acoustics: Pressure, Ma = 0.1 in the Label text field.

|

|

3

|

Locate the Data section. From the Dataset list, choose Study 3 - Acoustics, Ma = 0.05 and Ma = 0.1/Solution 4 (sol4).

|

|

4

|

|

5

|

|

7

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

In the Settings window for 3D Plot Group, type Acoustics: Sound Pressure Level, Ma = 0.05 in the Label text field.

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

In the associated text field, type TL (dB).

|

|

9

|

|

10

|

|

11

|

|

12

|

|

13

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Click to expand the Coloring and Style section. Find the Line markers subsection. From the Marker list, choose Point.

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Locate the Coloring and Style section. Find the Line markers subsection. From the Marker list, choose Point.

|

|

6

|

|

1

|

|

2

|

In the Settings window for Wall Distance Initialization, locate the Physics and Variables Selection section.

|

|

3

|

|

4

|

In the Physics and variables selection tree, select Component 1 (comp1)>Definitions>Perfectly Matched Layer 1 (pml1).

|

|

5

|

Click

|

|

1

|

|

2

|

|

3

|

|

4

|

In the Physics and variables selection tree, select Component 1 (comp1)>Definitions>Perfectly Matched Layer 1 (pml1).

|

|

5

|

Click

|