|

|

•

|

A direct solver (PARDISO) is used instead of the default iterative solver. In order to solve a Magnetic Fields problem with a direct solver it is necessary to apply the Gauge Fixing for A-Field feature.

|

|

•

|

The discretization order for the magnetic vector potential A is set to use Linear elements. The discretization order of the Jiles-Atherton auxiliary dependent variables is then automatically set to zero.

|

|

1

|

|

2

|

|

3

|

Click Add.

|

|

4

|

Click

|

|

5

|

In the Select Study tree, select Preset Studies for Selected Physics Interfaces>Coil Geometry Analysis.

|

|

6

|

Click

|

|

1

|

|

2

|

|

11.42 Ω

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

Select the object r1 only.

|

|

3

|

|

4

|

|

5

|

|

1

|

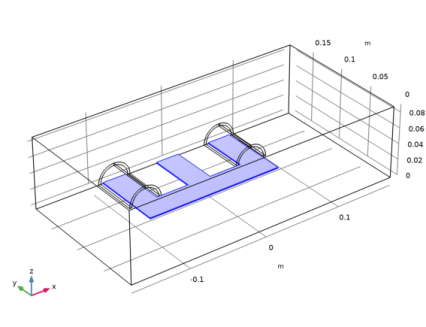

In the Model Builder window, under Component 1 (comp1)>Geometry 1 right-click Work Plane 1 (wp1) and choose Extrude.

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

Click to expand the Layers section. In the table, enter the following settings:

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

Select the object del1 only.

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

9

|

|

1

|

In the Model Builder window, under Component 1 (comp1) right-click Materials and choose Blank Material.

|

|

2

|

|

4

|

|

5

|

|

6

|

Click OK.

|

|

1

|

|

3

|

|

5

|

|

6

|

|

7

|

Click OK.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

2

|

|

4

|

In the Model Builder window, expand the Jiles-Atherton Hysteretic Material (mat3) node, then click Jiles-Atherton model parameters (ja).

|

|

6

|

Click the Edit button below the table.

|

|

7

|

Choose Diagonal and enter the diagonal elements according to the following table:

|

|

8

|

Click OK.

|

|

1

|

In the Model Builder window, under Component 1 (comp1)>Materials right-click Jiles-Atherton Hysteretic Material (mat3) and choose Rename.

|

|

2

|

In the Rename Material dialog box, type Jiles-Atherton Anisotropic Hysteretic Material in the New label text field.

|

|

3

|

Click OK.

|

|

1

|

In the Model Builder window, under Component 1 (comp1) right-click Magnetic Fields (mf) and choose Perfect Magnetic Conductor.

|

|

1

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

1

|

|

1

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

9

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

1

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

1

|

|

1

|

|

2

|

|

3

|

Click the Custom button.

|

|

4

|

|

6

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

In the Model Builder window, expand the Study 1>Solver Configurations>Solution 1 (sol1)>Dependent Variables 2 node, then click Magnetic vector potential (comp1.A).

|

|

4

|

|

5

|

|

6

|

|

8

|

|

9

|

|

10

|

|

11

|

|

12

|

|

13

|

|

14

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

In the Model Builder window, expand the Results>Magnetic Flux Density Norm (mf) node, then click Multislice 1.

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Click OK.

|

|

1

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

1

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

1

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

1

|

|

2

|

In the Settings window for Global, click Replace Expression in the upper-right corner of the y-Axis Data section. From the menu, choose Component 1 (comp1)>Magnetic Fields>Coil parameters>mf.ICoil_1 - Coil current - A.

|

|

1

|

|

2

|

|

3

|

|

4

|

Click

|

|

5

|

|

6

|

|

7

|

|

8

|

Click Replace.

|

|

9

|

|

10

|

|

11

|

|

12

|

Click OK.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

In the Rename 1D Plot Group dialog box, type Electric Current Harmonic Pollution in the New label text field.

|

|

3

|

Click OK.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Click

|

|

6

|

|

7

|

|

8

|

|

9

|

Click Replace.

|

|

1

|

|

2

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

Click OK.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

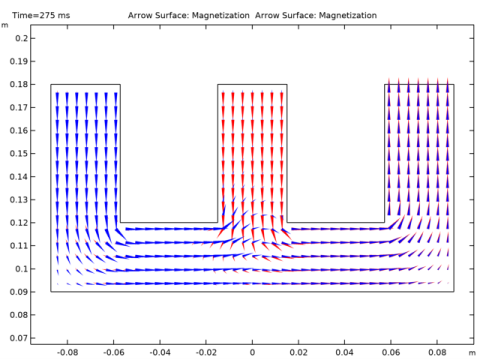

Locate the Arrow Positioning section. Find the x grid points subsection. In the Points text field, type 41.

|

|

6

|

|

1

|

|

2

|

|

3

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

5

|

|

1

|

|

2

|

|

3

|

Click OK.

|

|

1

|

|

2

|

|

3

|

|

4

|

Click OK.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|