|

|

5.998·107 S/m

|

|||

|

εr

|

|||

|

μr

|

103

|

|

1

|

|

2

|

|

3

|

Click Add.

|

|

4

|

|

5

|

Click

|

|

6

|

|

7

|

Click

|

|

1

|

|

2

|

|

3

|

Click Browse.

|

|

4

|

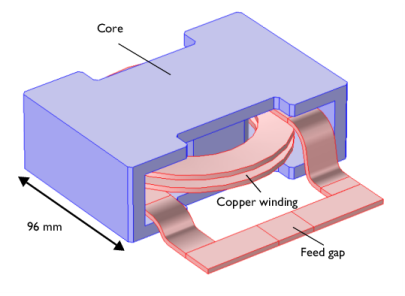

Browse to the model’s Application Libraries folder and double-click the file inductor_3d.mphbin.

|

|

5

|

Click Import.

|

|

1

|

|

2

|

|

3

|

|

4

|

Click to expand the Layers section. In the table, enter the following settings:

|

|

5

|

|

1

|

|

2

|

|

3

|

|

1

|

|

3

|

|

4

|

|

5

|

Click OK.

|

|

1

|

|

3

|

|

4

|

|

5

|

Click OK.

|

|

1

|

|

3

|

|

4

|

|

5

|

Click OK.

|

|

1

|

|

3

|

|

4

|

|

5

|

Click OK.

|

|

1

|

|

3

|

|

4

|

|

5

|

Click OK.

|

|

1

|

|

3

|

|

4

|

|

5

|

Click OK.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

In the tree, select AC/DC>Copper.

|

|

4

|

|

5

|

In the tree, select Built-in>Air.

|

|

6

|

|

7

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

Click OK.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

In the Model Builder window, expand the Component 1 (comp1)>Magnetic Fields (mf)>Coil 1>Geometry Analysis 1 node, then click Input 1.

|

|

1

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

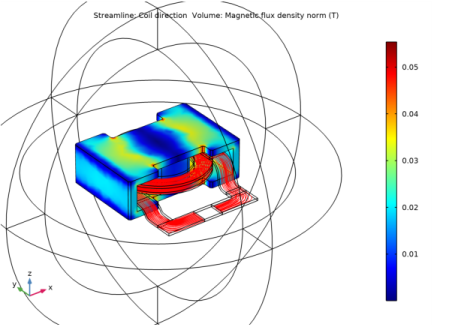

In the Settings window for Streamline, click Replace Expression in the upper-right corner of the Expression section. From the menu, choose Component 1 (comp1)>Magnetic Fields>Coil parameters>mf.coil1.eCoilx,...,mf.coil1.eCoilz - Coil direction.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

4

|

Click

|

|

1

|

Go to the Table window.

|

|

1

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

1

|

|

2

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

4

|

Click

|

|

1

|

Go to the Table window.

|

|

1

|

|

2

|

|

3

|

Find the Physics interfaces in study subsection. In the table, clear the Solve check box for Electrical Circuit (cir).

|

|

4

|

|

5

|

|

6

|

|

1

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

Click OK.

|

|

1

|

|

2

|

|

3

|

In the tree, select AC/DC>Copper.

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

1

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

1

|

|

2

|

|

3

|

|

4

|

Locate the Constitutive Relation B-H section. From the Magnetization model list, choose Magnetic losses.

|

|

5

|

From the μ′ list, choose User defined. From the μ′′ list, choose User defined. In the μ′ text field, type 1200.

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

Click

|

|

5

|

|

6

|

|

7

|

|

8

|

Click Replace.

|

|

9

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

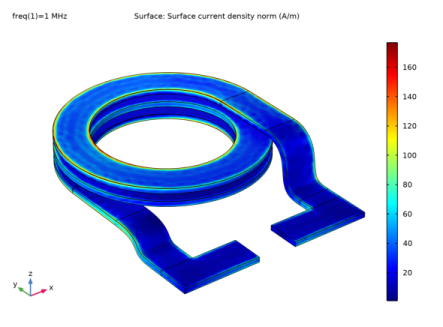

In the Settings window for Surface, click Replace Expression in the upper-right corner of the Expression section. From the menu, choose Component 1 (comp1)>Magnetic Fields>Currents and charge>mf.normJs - Surface current density norm - A/m.

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

In the Settings window for Global, click Replace Expression in the upper-right corner of the y-Axis Data section. From the menu, choose Component 1 (comp1)>Magnetic Fields>Ports>mf.Zport_1 - Lumped port impedance - Ω.

|

|

3

|

|

4

|

|

5

|

Click Replace Expression in the upper-right corner of the y-Axis Data section. From the menu, choose Component 1 (comp1)>Magnetic Fields>Ports>mf.Zport_1 - Lumped port impedance - Ω.

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|