This tutorial analyzes a hypothetical absolute pressure sensor used as an example in the book Practical MEMS, by V. Kaajakari (V. Kaajakari, Practical MEMS, Small Gear Publishing, Las Vegas, pp. 207–209, 2009). Initially the sensitivity of the device is assessed under ideal operating conditions. Then the effect of packaging induced stress is analyzed, both in terms of the device sensitivity to pressure and an induced sensitivity to temperature.

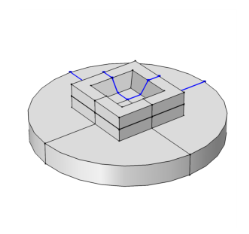

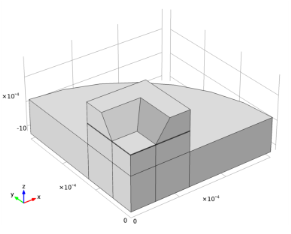

The device geometry is shown in Figure 3. The pressure sensor is part of a silicon die that has been bonded to a metal plate at 70°C. The COMSOL model takes advantage of the symmetry in the geometry and models only a single quadrant of the device.

A detailed 2D section through the functional part of the device is shown in Figure 4. A thin membrane is held at a fixed potential of 1 V. The membrane is separated from a ground plane by a chamber sealed under high vacuum. The sides of the chamber are insulating to prevent a connection between the membrane and the ground plane (for simplicity the insulating layer is not modeled explicitly in the COMSOL Multiphysics model — this approximation will have little effect on the results of the study).