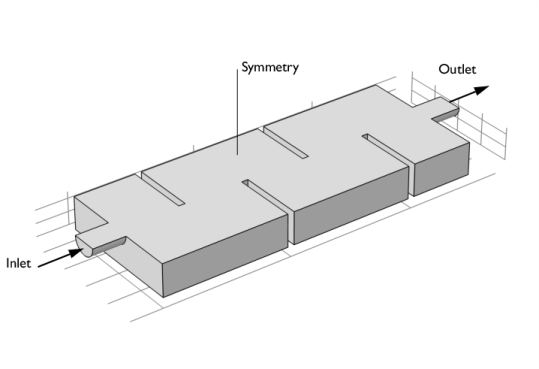

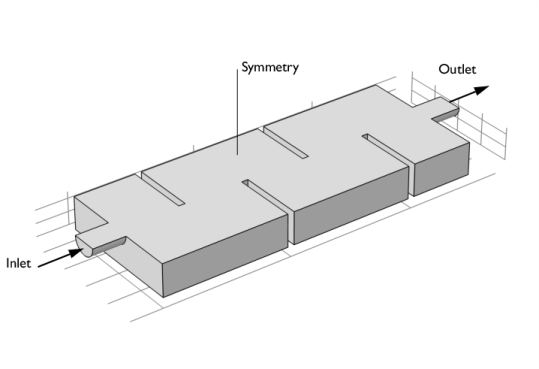

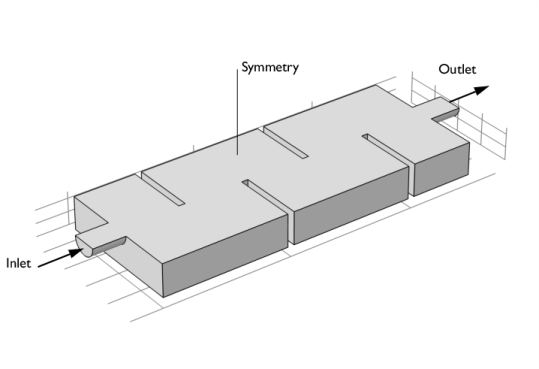

The model geometry along with some boundary conditions is shown in Figure 10. The full reactor has a symmetry plane, which is utilized to reduce the size of the component.

Here ν is the kinematic viscosity. The high Reynolds number clearly indicates that the flow is turbulent and a turbulence model must be applied. In this case, you will use the

k-

ε model. It is commonly used in industrial applications, because it is both relatively robust and computationally inexpensive compared to more advanced turbulence models. One major reason to why the

k-

ε model is inexpensive is that it employs wall functions to describe the flow close to walls instead of resolving the very steep gradients there. All boundaries are walls in

Figure 10 except the inlet, the outlet, and the symmetry plane.

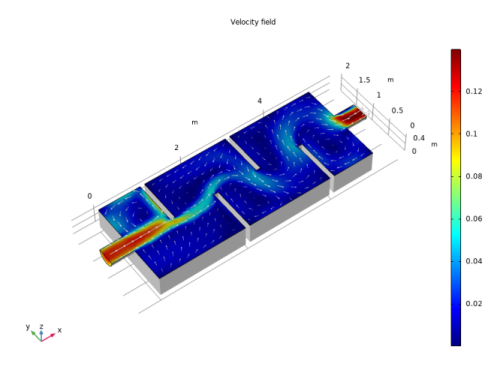

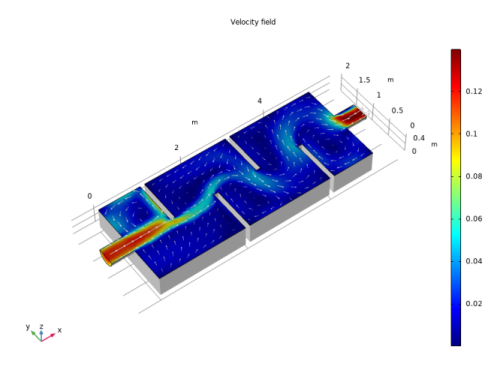

The velocity field in the symmetry plane is shown in Figure 11. The jet from the inlet hits the edge of the first baffle, which splits the jet. One half creates a strong recirculation zone in the first “chamber”. The other half continues downstream into the reactor and gradually spreads out. The velocity magnitude decreases as more fluid is entrained into the jet.

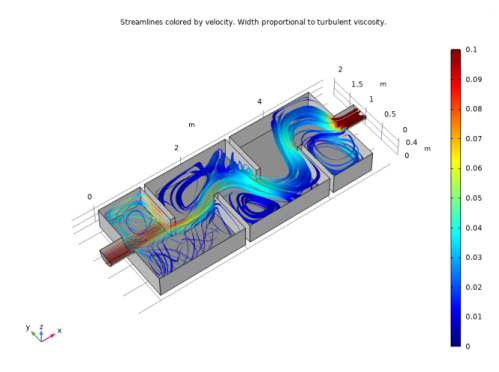

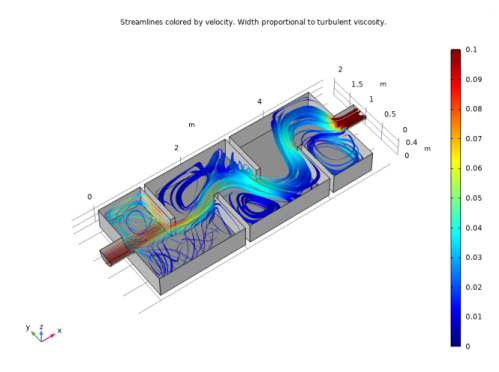

Figure 12 gives a more complete picture of the mixing process in the reactor. The streamlines are colored by the velocity magnitude, and their widths are proportional to the turbulent viscosity. Wide lines hence indicate a high degree of mixing. The turbulence in this model is mainly produced in the shear layers between the central jet and the recirculation zones. The mixing can be seen to be relatively weak near the entrance to the reactor and to increase further downstream.