You are viewing the documentation for an older COMSOL version. The latest version is

available here.

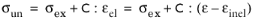

For a linear elastic material, Hooke’s law relates the undamaged stress tensor

σun to the elastic strain tensor:

(3-76)

here,  is the fourth order elasticity tensor

is the fourth order elasticity tensor, “:” stands for the double-dot tensor product (or double contraction). The elastic strain

εel is the difference between the total strain

ε and all inelastic strains

εinel. There may also be an extra stress contribution

σex, with contributions from initial, external or viscoelastic stresses.

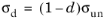

For the scalar damage models, the damaged stress tensor

σd is computed from the undamaged stress as

(3-77)

(3-78)

here, εeq is the equivalent strain, a scalar measure of the elastic strain; and

κ is a state variable. The evolution of the state variable

κ follows the Kuhn-Tucker loading/unloading conditions

In this formulation, κ is the maximum value of

εeq in the load history. The damage variable

d is then computed as a function of the state variable

κ and other parameters.

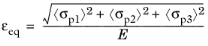

Different damage models use different definitions for the equivalent strain εeq. The

Rankine damage model defines the equivalent strain from the largest undamaged principal stress

σp1 as

(3-79)

here, the symbol “<>” are the Macaulay brackets, and E is Young’s modulus. The Macaulay brackets are used since in this formulation only tensile (positive) stresses cause damage.

The Smooth Rankine damage model defines the equivalent strain from the three undamaged principal stresses

(3-80)

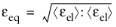

The Euclidean Norm of the elastic strain tensor can also be used as a measure for the equivalent strain

(3-81)

For Mazars damage for concrete, it is also possible to select from

Mazars or

Modified Mazars equivalent strain. For Mazars equivalent strain is defined as

(3-82)

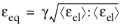

In the modified Mazars equivalent strain (Ref. 2 and

Ref. 3), a correction factor

γ is added to improve the approximation of the failure surface of concrete in multiaxial compression.

(3-83)

It is also possible to apply a User defined expression for defining the equivalent strain as a function of undamaged stress, stress components or strains.

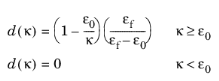

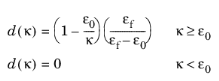

(3-84)

,

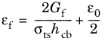

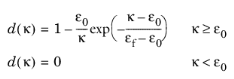

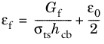

,Here, ε0 denotes the onset of damage, computed from the tensile strength

σts and Young’s modulus

E, so that

ε0 = σts/E. The parameter

εf is derived from parameters such as the tensile strength, the characteristic element size

hcb and the fracture energy per unit area

Gf, or the fracture energy per unit volume

gf.

(3-85)

The Exponential strain softening law defines the damage evolution from

(3-86)

(3-87)

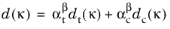

The Mazars damage for concrete utilizes two different damage evolution laws, one for tensile damage and another for compressive damage. These two damage functions are combined as

(3-88)

here, αt and

αc are weight functions depending on the current stress state, and

β determines the response in shear, that is, the evolution of the combined damage function in states where both damage functions are active.

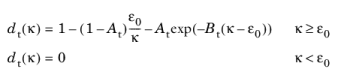

To define the tensile damage evolution law dt(κ) (

Ref. 3), it is possible to use either

Linear strain softening,

Exponential strain softening, or

Mazars damage evolution function, which is obtained by a combination of linear and exponential strain softening

(3-89)

Here, At and

Bt are tensile damage evolution parameters, and

ε0t is the tensile strain threshold.

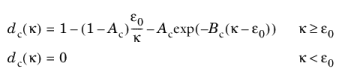

The compressive damage evolution law dc(κ) is obtained by the

Mazars damage evolution function

(3-90)

Here, Ac and

Bc are compressive damage evolution parameters, and

ε0c is the compressive strain threshold. Both the tensile and compressive damage evolution laws can also be specified by

User defined expressions.

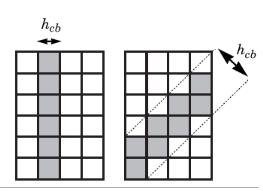

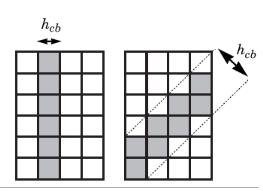

This simplest regularization technique is based on stress-strain curves (damage evolution laws) that depend on the mesh and element characteristics. The method is often called the Crack Band method (

Ref. 4,

Ref. 5). The method regularizes the solution from a global viewpoint, which dissipates the correct amount of energy during strain localization. The main difficulty in using the crack band method is to find the correct width of the crack band,

hcb, which can depend on the element size and shape as well as the order of the interpolation and the current stress state (that is, inclination of the crack with respect to the mesh).

The crack band width hcb is then used to modify the

Damage Evolution law in which the damage variable

d(κ) is computed. Note that the damage evolution laws (

Equation 3-89 and

Equation 3-90) are unaffected by the crack band method.

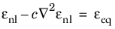

The Implicit Gradient method (

Ref. 6) enforces a predefined width of the damage zone through a localization limiter. This is achieved by adding a nonlocal strain variable, the

nonlocal equivalent strain εnl, through an additional PDE where the equivalent strain

εeq acts as source term. This PDE is solved simultaneously with the displacement field:

(3-91)

Here, the parameter c controls the width of the localization band. This parameter is defined from the Internal length scale lint, and the geometry dimension

n (two or three dimension)

(3-92)

The strain-based formulation for the damage model (Equation 3-78) is then redefined by the nonlocal equivalent strain

εnl instead of the equivalent strain

εeq

(3-93)

,

,