|

|

•

|

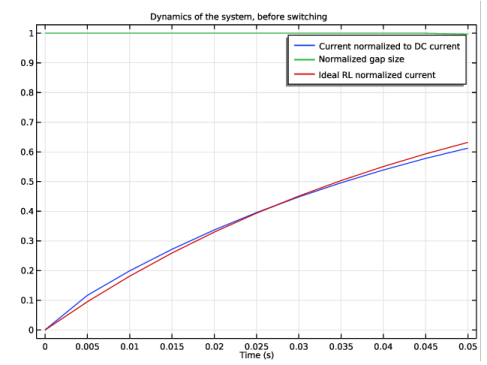

Before plunger motion: Figure 7 shows the first stage of the simulation, when the spring is not yet compressed. Blue and green lines represent normalized currents and gap size respectively. Red line is an exponential fit for the RL current dynamics of the initially non-moving inductor — the response of an ideal system.

|

|

•

|

During plunger motion: the compression of the spring and the resulting closure of the gap are visualized in Figure 8. Normalized currents and gap size are represented by blue and green lines respectively, the red line showing instead the mechanical power (which is nonzero only during the motion of the plunger).

|

|

•

|

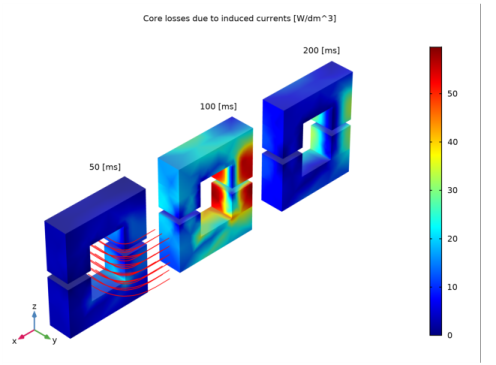

After plunger motion: Figure 9 refers to the last stage of simulation, when the spring is completely compressed. The red line shows the induction losses in the core, which are significant during the movement of the plunger. Depending on the details of the device and the desired performance, this aspect may need to be taken into account during the design process. After the movement is completed, the current starts increasing again as expected in a (nonlinear) RL circuit.

|

|

1

|

|

2

|

|

3

|

Click Add.

|

|

4

|

|

5

|

Click Add.

|

|

6

|

Click Study.

|

|

7

|

|

8

|

Click Done.

|

|

1

|

|

2

|

|

3

|

|

4

|

Browse to the model’s Application Libraries folder and double-click the file power_switch_multibody_parameters.txt.

|

|

1

|

|

2

|

|

3

|

Right-click Core Section and choose Rectangle six times, entering the following settings in each Rectangle node:

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

Click to expand the Layers section. In the table, enter the following settings:

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

|

3

|

|

4

|

On the object c1, select Domain 1 only.

|

|

5

|

|

1

|

In the Model Builder window, under Global Definitions right-click Geometry Parts and choose 3D Part.

|

|

2

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

4

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

In the Definitions toolbar, use the buttons to create Selection nodes according to the following table:

|

|

1

|

In the Model Builder window, under Component 1 (comp1) right-click Materials and choose Blank Material.

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

1

|

|

1

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

9

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

Locate the Homogenized Multi-Turn Conductor section. In the N text field, type filling*d1*d2/a_coil.

|

|

9

|

|

1

|

|

2

|

|

3

|

|

1

|

|

1

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

Locate the Density section. From the ρ list, choose User defined. In the Model Builder window, click Rigid Domain 1.

|

|

1

|

|

2

|

In the Settings window for Mass and Moment of Inertia, locate the Mass and Moment of Inertia section.

|

|

3

|

|

1

|

|

2

|

|

3

|

Specify the F vector as

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

9

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

9

|

|

1

|

In the Model Builder window, under Component 1 (comp1) right-click Definitions and choose Variables.

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

In the Settings window for 3D Plot Group, type Preprocessing: Air Gap Parameterization and Coil Direction in the Label text field.

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

In the Model Builder window, right-click Preprocessing: Air Gap Parameterization and Coil Direction and choose Streamline.

|

|

3

|

In the Settings window for Streamline, click Replace Expression in the upper-right corner of the Expression section. From the menu, choose Model>Component 1>Magnetic Fields>Coil parameters>mf.coil1.eCoilx,...,mf.coil1.eCoilz - Coil direction (spatial frame).

|

|

4

|

Locate the Coloring and Style section. Find the Line style subsection. From the Type list, choose Tube.

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

Click to expand the Values of Dependent Variables section. Find the Values of variables not solved for subsection. From the Settings list, choose User controlled.

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

In the Model Builder window, expand the Study 2 (Time Dependent)>Solver Configurations>Solution 2 (sol2)>Dependent Variables 1 node, then click Magnetic vector potential (spatial frame) (comp1.A).

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

9

|

|

10

|

|

11

|

|

12

|

|

13

|

In the Model Builder window, expand the Study 2 (Time Dependent)>Solver Configurations>Solution 2 (sol2)>Time-Dependent Solver 1 node.

|

|

14

|

|

15

|

|

16

|

|

17

|

|

18

|

|

19

|

Find the Algebraic variable settings subsection. From the Error estimation list, choose Exclude algebraic.

|

|

20

|

|

21

|

|

22

|

|

23

|

|

24

|

|

25

|

|

26

|

Click to expand the Method and Termination section. From the Jacobian update list, choose On every iteration.

|

|

27

|

In the Study toolbar, click Compute. The solution process will need about 50 minutes on a typical workstation.

|

|

1

|

In the Model Builder window, under Results>Preprocessing: Air Gap Parameterization and Coil Direction click Volume 1.

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

1

|

In the Model Builder window, expand the Results>Magnetic Flux Density Norm (mf) node, then click Multislice 1.

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

9

|

|

10

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

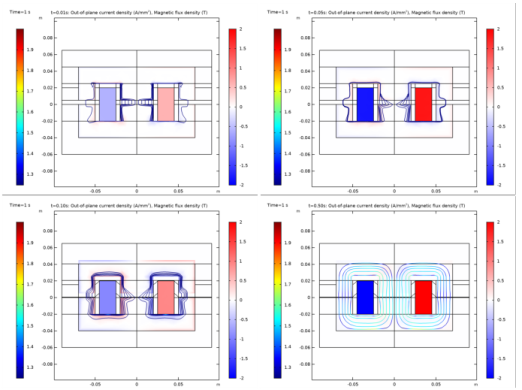

In the Title text area, type t=0.01s: Out-of-plane current density (A/mm<sup>2</sup>), Magnetic flux density (T).

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

9

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

In the Model Builder window, right-click Current Density and Magnetic Flux Lines and choose Streamline.

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

Click to expand the Coloring and Style section. In the Dynamics, Before Switching toolbar, click Plot.

|

|

1

|

|

2

|

|

3

|

Locate the Title section. In the Title text area, type Dynamics of the system during the switching phase.

|

|

1

|

In the Model Builder window, expand the Results>Dynamics During Switching node, then click Global 1.

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

In the table, select the third row then click the Delete button below the table.

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

8

|