|

|

1

|

|

2

|

In the Select Physics tree, select AC/DC>Electric Fields and Currents>Electric Currents in Shells (ecis).

|

|

3

|

Click Add.

|

|

4

|

Click Study.

|

|

5

|

|

6

|

Click Done.

|

|

1

|

|

2

|

In the tree, select Built-in>Copper.

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

In the Model Builder window, under Global Definitions right-click Materials and choose Layered Material.

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

In the xw text field, type -6 -6 -5.5 -5.5 -4 -4 4.5 4.5 -3 -3 3.5 3.5 -2 -2 -2 2.5 2.5 -1 -1 -0.5 -0.5 2 2 -1.5 -1.5 -1.5 3 3 -2.5 -2.5 4 4 -3.5 -3.5 -5.5 -5.5 -6.

|

|

5

|

In the yw text field, type 0.5 2 2 1.5 1.5 3.5 3.5 -4 -4 2.5 2.5 -3 -3 -2 1.5 1.5 -2 -2 -1 -1 -1.5 -1.5 1 1 -2 -2.5 -2.5 2 2 -3.5 -3.5 3 3 1 1 0.5 0.5.

|

|

6

|

|

7

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

Click in the Graphics window and then press Ctrl+A to select all objects.

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

Click in the Graphics window and then press Ctrl+A to select all objects.

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

Locate the Selections of Resulting Entities section. Find the Cumulative selection subsection. Click New.

|

|

4

|

|

5

|

Click OK.

|

|

1

|

|

2

|

|

3

|

Locate the Selections of Resulting Entities section. Find the Cumulative selection subsection. Click New.

|

|

4

|

|

5

|

Click OK.

|

|

1

|

|

2

|

|

3

|

Locate the Selections of Resulting Entities section. Find the Cumulative selection subsection. Click New.

|

|

4

|

|

5

|

Click OK.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

Click OK.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

Click OK.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

Click OK.

|

|

8

|

|

9

|

Click Add.

|

|

10

|

|

11

|

Click OK.

|

|

12

|

|

1

|

|

2

|

In the tree, select Built-in>Air.

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

In the Settings window for Layered Material Stack, type Upper metallization in the Label text field.

|

|

3

|

|

4

|

|

1

|

|

2

|

|

4

|

|

5

|

|

1

|

In the Model Builder window, under Component 1 (comp1)>Materials>Upper metallization (stlmat1) click Layered Material Link 1 (stlmat1.stllmat1).

|

|

2

|

|

1

|

|

2

|

In the Settings window for Layered Material Stack, type Lower metallization in the Label text field.

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

In the Model Builder window, under Component 1 (comp1)>Materials>Vias (stlmat4) click Layered Material Link 1 (stlmat4.stllmat1).

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

6

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

Locate the Shell Properties section. From the Layer list, choose Intersections (stlmat3)-[lmat2]-[lmat1]-[...].

|

|

5

|

Specify the Selection vector as

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

Click the Custom button.

|

|

4

|

Locate the Geometric Entity Selection section. From the Geometric entity level list, choose Boundary.

|

|

5

|

|

6

|

|

8

|

|

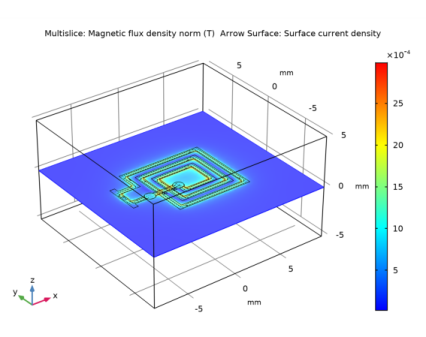

1

|

In the Model Builder window, expand the Results>Magnetic Flux Density Norm (mf) node, then click Multislice 1.

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

In the Settings window for Arrow Surface, click Replace Expression in the upper-right corner of the Expression section. From the menu, choose Model>Component 1>Magnetic Fields>mf.scu1.Js0x,...,mf.scu1.Js0z - Surface current density.

|

|

3

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

In the Settings window for Global Evaluation, click Add Expression in the upper-right corner of the Expressions section. From the menu, choose Model>Component 1>Electric Currents in Shells>Terminals>ecis.V0_1 - Terminal voltage - V.

|

|

3

|

Locate the Expressions section. In the table, enter the following settings:

|

|

mΩ

|

||

|

4

|

Click Evaluate.

|