|

|

1

|

|

2

|

In the Select Physics tree, select AC/DC>Electric Fields and Currents>Electrostatics, Boundary Elements (esbe).

|

|

3

|

Click Add.

|

|

4

|

Click Study.

|

|

5

|

In the Select Study tree, select Preset Studies for Selected Physics Interfaces>Stationary Source Sweep.

|

|

6

|

Click Done.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

Select the object r1 only.

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

In the tree, select Built-in>Air.

|

|

3

|

|

4

|

In the tree, select Built-in>Nylon.

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

1

|

In the Model Builder window, under Component 1 (comp1) right-click Electrostatics, Boundary Elements (esbe) and choose Charge Conservation.

|

|

1

|

|

1

|

|

1

|

|

1

|

|

1

|

|

1

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

In the Model Builder window, under Component 1 (comp1) click Electrostatics, Boundary Elements (esbe).

|

|

2

|

In the Settings window for Electrostatics, Boundary Elements, click to expand the Discretization section.

|

|

3

|

|

1

|

|

2

|

|

3

|

In the Model Builder window, expand the Study 1>Solver Configurations>Solution 1 (sol1)>Stationary Solver 1 node.

|

|

4

|

Right-click Study 1>Solver Configurations>Solution 1 (sol1)>Stationary Solver 1>Direct and choose Enable.

|

|

5

|

|

1

|

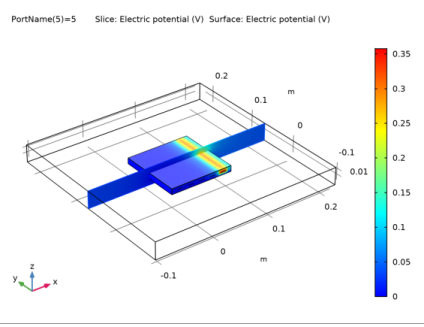

In the Model Builder window, expand the Electric Potential, Domains (esbe) node, then click Slice 1.

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

In the Model Builder window, expand the Results>Derived Values node, then click Maxwell capacitance (esbe, dset1).

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

Go to the Table window.

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

9

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

1

|

|

3

|

|

4

|

Click in the Graphics window and then press Ctrl+A to select both domains.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

Click Add.

|

|

5

|

Click Range.

|

|

6

|

|

7

|

|

8

|

|

9

|

Click Replace.

|

|

10

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

4

|

|

5

|

|

7

|