where E is the variable for the internal energy.

The ∇t operator is the tangential derivative in the thin structure boundary, and the

∇n operator is the derivation operator along the extra dimension which is normal to the thin structure (see

Tangential and Normal Gradients). The subscript

s appended on

E (and

T in the following) is here to recall that this variable lives in the product space of the thin structure.

Equation 4-39 comes along with Fourier’s law of conduction:

Here, ds is the length of the extra dimension, or equivalently the thickness of the thin structure, and

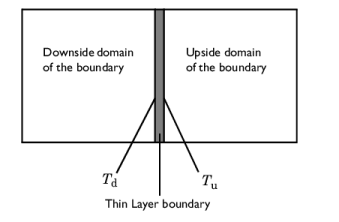

Tu and

Td are the temperature at the upside and the downside of the thin structure.

where ds is the layer thickness (SI unit: m). The heat source

Q is a density distributed in the layer while

q0 is the received out-of-plane heat flux.

When Equation 4-42 is solved in a boundary adjacent to a domain modeling heat transfer, the two entities exchange a certain amount of heat flux according to:

In this coupling relation, the outgoing heat flux n ⋅ q leaves the domain and is received in the source term

q0 by the adjacent thin layer modeled as a boundary. From the point of view of the domain, and neglecting thermoelastic effects, the following heat source is received from the thin structure:

where ds is the layer thickness (SI unit: m). The heat source

Q is a density distributed in the layer while

q0 is the received out-of-plane heat flux.

When Equation 4-45 is solved in a boundary adjacent to a domain modeling heat transfer, the two entities exchange a certain amount of heat flux according to:

In this coupling relation, the outgoing heat flux n ⋅ q leaves the domain and is received in the source term

q0 by the adjacent thin layer modeled as a boundary. From the point of view of the domain, and neglecting thermoelastic effects, the following heat source is received from the thin structure:

To evaluate the normal gradient operation, ∇n, temperatures

Tu and

Td are introduced for the upside and downside of the thin structure boundary. They are defined from the heat flux across the thin resistive structure. At the middle of the thickness, the temperature,

T1 ⁄ 2, is approximated by

(1 ⁄ 2)(Tu + Td). The term

∇n ⋅ (−dsk∇nT) is then given by:

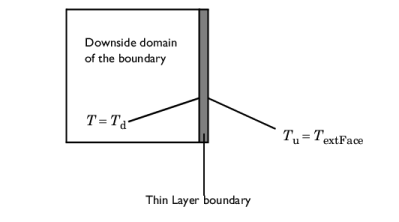

On exterior boundaries, it introduces a new degree of freedom represented by the variable TextFace. Depending on whether the heat domain is on the upside or the downside of the boundary,

TextFace, is equal to

Tu or

Td and the same thing goes for the dependent variable

T. An example is illustrated in the figure below:

Table 4-3 summarizes the formulations available within the thin structure features of the Heat Transfer (

ht) and Heat Transfer in Shells (

htlsh) interfaces.