.

.|

•

|

Thin plate (the default), the model where the losses due to heat conduction are negligible.

|

|

•

|

Thick plate, the model that takes the thermal effects into account.

|

|

•

|

Asymptotic (legacy) model, the model available in COMSOL Multiphysics version 5.2a and earlier.

|

|

•

|

|

•

|

|

•

|

Area porosity σ, that is, the holes’ fraction of the boundary surface area, a dimensionless number between 0 and 1. The default is 0.1, which means 10% of the plate area consists of holes.

|

|

•

|

End correction to the resistance δresist and the reactance δreactt (SI unit: m). The default built-in sets δresist = δresist = 4dh/3π. Otherwise, select the user defined.

|

|

•

|

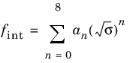

Hole-hole interaction fint, a dimensionless function that accounts for the influence of the porosity on the end correction. The default is the built-in Fok function (using eight terms):

|

|

•

|

Discharge coefficient (linear)

|

|

•

|

|

•

|

Discharge coefficient (nonlinear)

|

|

•

|

User-defined resistance θ(user) , a contribution to the resistive part of the impedance, dimensionless. The default is 0.

|

|

•

|

User-defined resistance χ(user) , a contribution to the reactive part of the impedance, dimensionless. The default is 0.

|

|

•

|

|

•

|

Speed of sound c (SI unit: m/s).

|

|

•

|

Dynamic viscosity μ (SI unit: Pa·s).

|

|

•

|

|

•

|

|

•

|

|

The transfer impedance models from the list above are only valid for the perforates with round holes. For other types of perforates — with squared or slit-shaped holes — the values of some parameters can considerably differ from that of the suggested built-in perforates. It is recommended that you use the Interior Impedance/Pair Impedance condition to enter a user-defined model in such a case. The user-defined impedance can be obtained from a thermoviscous acoustic submodel (see The Thermoviscous Acoustics, Frequency Domain Interface) as demonstrated in the Acoustic Muffler with Thermoviscous Acoustic Impedance Lumping model.

|