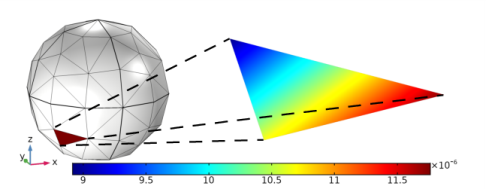

The discretization error not only applies to the position on the sphere, but also to the normal direction and Gaussian curvatures of the surface, all of which can be used in geometrical optics simulation. A relative error like the one shown above (10-5) might be sufficiently small for some simulation results, but in geometrical optics such an error might translate to tens of additional wavelengths in spot size—large enough to invalidate the results of the simulation entirely, unless adequate precautions are taken.