|

|

1

|

|

2

|

Click Done.

|

|

1

|

|

2

|

|

3

|

Click Browse.

|

|

5

|

Click Import.

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

On the object imp1, select Domain 1 only.

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

9

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

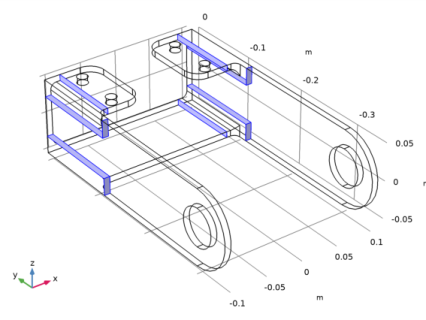

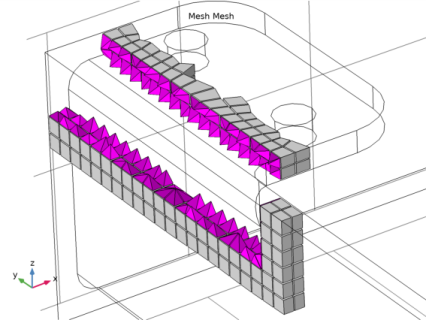

On the object fin, select Edges 123–164 only, by clicking the Select Box button on the Graphics toolbar, and using the mouse to select the edges highlighted below.

|

|

4

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

Click the Custom button.

|

|

4

|

|

5

|

|

1

|

In the Model Builder window, under Component 1 (comp1)>Mesh 1 right-click Swept 1 and choose Distribution.

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

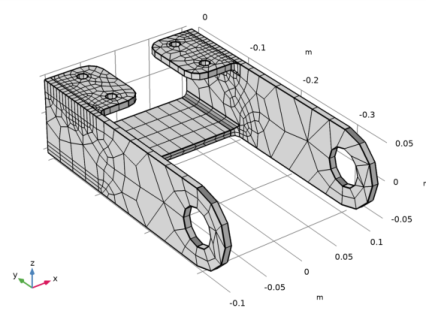

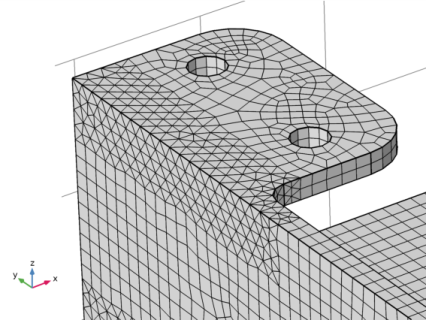

Click the Zoom Box button on the Graphics toolbar and then use the mouse to zoom in to the corner on the bracket displayed below to get a better view of the elements.

|

|

9

|

|

1

|

In the Model Builder window, under Component 1 (comp1)>Geometry 1 right-click Partition Domains 1 (pard1) and choose Delete.

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

Right-click Component 1 (comp1)>Geometry 1>Work Plane 1 (wp1)>Plane Geometry>Rectangle 1 (r1) and choose Duplicate.

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

Right-click Component 1 (comp1)>Geometry 1>Work Plane 1 (wp1)>Plane Geometry>Rectangle 3 (r3) and choose Duplicate.

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

1

|

|

2

|

|

4

|

|

5

|

Locate the Selections of Resulting Entities section. Select the Resulting objects selection check box.

|

|

6

|

|

1

|

|

2

|

Select the object imp1 only.

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

5

|

|

1

|

|

2

|

|

3

|

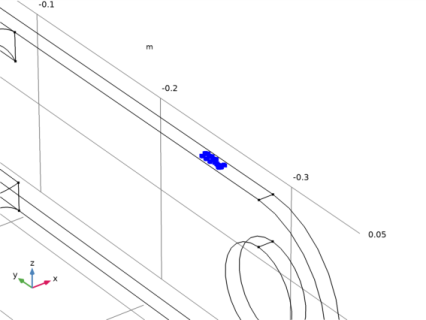

Click the Zoom Box button on the Graphics toolbar and then use the mouse to zoom in to the region below.

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

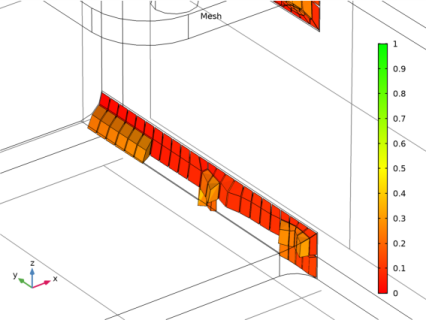

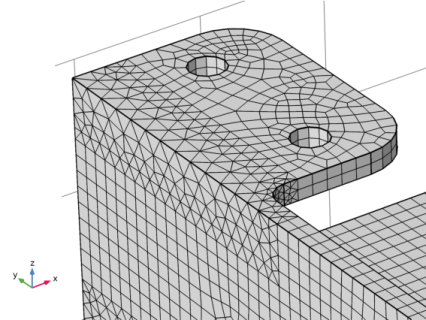

Click the Zoom Box button on the Graphics toolbar and then use the mouse to zoom in to the region below.

|

|

6

|

|

7

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

Click the Zoom Box button on the Graphics toolbar and then use the mouse to zoom in to get a better view of the elements.

|