|

|

1

|

|

2

|

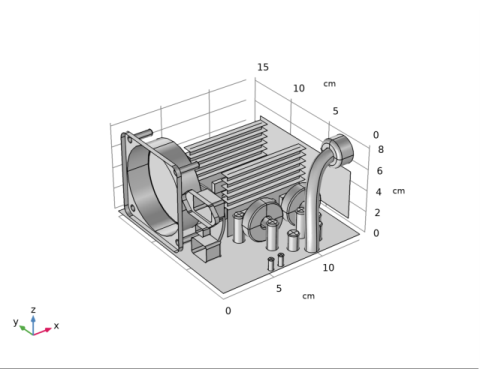

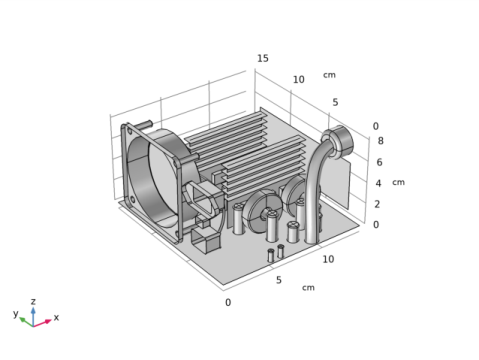

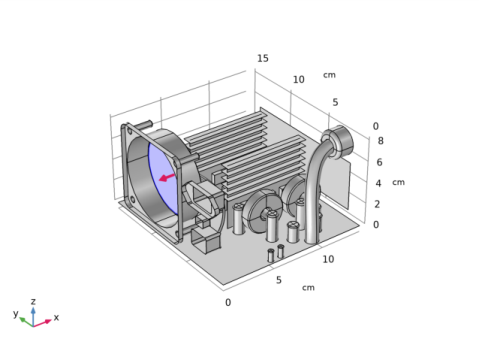

Browse to the model’s Application Libraries folder and double-click the file electronic_enclosure_cooling_geom.mph.

|

|

1

|

|

2

|

|

3

|

Locate the Definition section. In the Expression text field, type 12084*OR^6-42281*OR^5+60989*OR^4-46559*OR^3+19963*OR^2-4618.5*OR+462.89.

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

Click Plot.

|

|

1

|

|

2

|

|

3

|

In the tree, select Built-In>Air.

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

9

|

In the tree, select Built-In>Aluminum.

|

|

10

|

|

11

|

In the tree, select Built-In>Copper.

|

|

12

|

|

13

|

In the tree, select Built-In>Silicon.

|

|

14

|

|

15

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

In the Model Builder window, under Component 1 (comp1) right-click Materials and choose Layers>Single Layer Material.

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

Click OK.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

In the tree, select Built-In>Copper.

|

|

3

|

Click OK.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

Click to expand the Material Properties section. In the Material properties tree, select Basic Properties>Heat Capacity at Constant Pressure.

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

9

|

|

10

|

|

11

|

|

12

|

In the Diagonal table, enter the following settings:

|

|

13

|

click OK.

|

|

1

|

|

2

|

|

3

|

|

1

|

In the Model Builder window, under Component 1 (comp1)>Heat Transfer in Solids and Fluids (ht) click Fluid 1.

|

|

2

|

|

3

|

|

1

|

In the Model Builder window, under Component 1 (comp1)>Heat Transfer in Solids and Fluids (ht) click Initial Values 1.

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

In the Settings window for Heat Source, type Heat Source 2: Large Transformer Coil in the Label text field.

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

In the Settings window for Heat Source, type Heat Source 3: Small Transformer Coils in the Label text field.

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

In the Settings window for Heat Source, type Heat Source 5: Large Capacitors in the Label text field.

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

In the Settings window for Heat Source, type Heat Source 6: Medium Capacitors in the Label text field.

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

In the Settings window for Heat Source, type Heat Source 7: Small Capacitors in the Label text field.

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

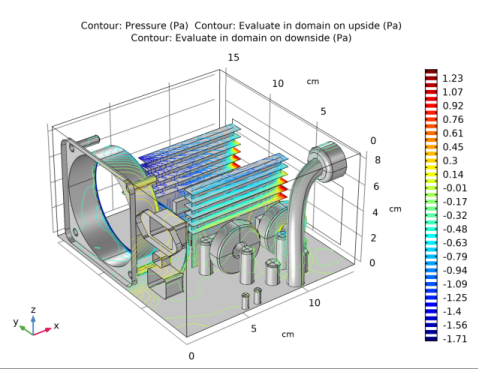

Locate the Parameters section. From the Static pressure curve list, choose Static pressure curve data.

|

|

6

|

|

7

|

Browse to the model’s Application Libraries folder and double-click the file electronic_enclosure_cooling_fan_curve.txt.

|

|

8

|

Locate the Static Pressure Curve Interpolation section. From the Interpolation function type list, choose Piecewise cubic.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

In the Model Builder window, under Component 1 (comp1)>Turbulent Flow, Algebraic yPlus (spf) click Initial Values 1.

|

|

2

|

|

3

|

Specify the u vector as

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

Click to expand the Advanced Settings section. In order to get a regular mesh, select the option to adjust the mesh position on the edges in the swept direction.

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

Click the Custom button.

|

|

5

|

|

7

|

|

9

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Click the Custom button.

|

|

6

|

|

8

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

Click the Custom button.

|

|

4

|

|

6

|

|

8

|

|

10

|

|

12

|

|

14

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

Click to expand the Corner Settings section. From the Handling of sharp edges list, choose Trimming.

|

|

1

|

In the Model Builder window, expand the Boundary Layers 1 node, then click Boundary Layer Properties 1.

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

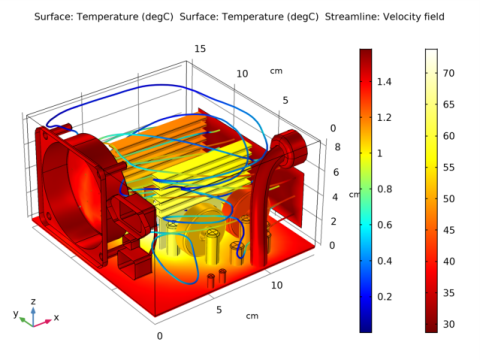

In the Settings window for Streamline, click Replace Expression in the upper-right corner of the Expression section. From the menu, choose Model>Component 1>Turbulent Flow, Algebraic yPlus>Velocity and pressure>u,v,w - Velocity field.

|

|

3

|

|

4

|

Locate the Coloring and Style section. Find the Line style subsection. From the Type list, choose Tube.

|

|

1

|

|

2

|

In the Settings window for Color Expression, click Replace Expression in the upper-right corner of the Expression section. From the menu, choose Model>Component 1>Turbulent Flow, Algebraic yPlus>Velocity and pressure>spf.U - Velocity magnitude - m/s.

|

|

3

|