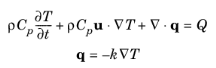

This node models heat transfer in shape memory alloys, and accounts for the Martensite and Austenite composition. This feature is designed to be coupled with the Shape Memory Alloy feature of the Structural Mechanics interface which computes the alloy composition from the mechanical and thermal loads. Changes in Martensite and Austenite composition modify the alloys thermal properties (thermal conductivity and heat capacity), and release (from Austenite to Martensite state) or absorb (from Martensite to Austenite state) energy.

This section is available when a temperature-dependent density is used. On the material frame, the density is evaluated onto a reference temperature to ensure mass conservation in the presence of temperature variations. By default the Common model input is used. This corresponds to the variable

minput.Tempref, which is set by default to 293.15 [K]. To edit it, click the

Go to Source button (

), and in the

Common Model Inputs node under

Global Definitions, set a value for the

Volume reference temperature in the

Expression for remaining selection section.

The other options are User defined and all temperature variables from the physics interfaces included in the model.

This section is available when temperature-dependent material properties are used. By default the temperature of the parent interface is used and the section is not editable. To edit the Temperature field, click

Make All Model Inputs Editable (

). The available options are

User defined (default),

Common model input (the

minput.T variable, set to 293.15 [K] by default) and all temperature variables from the physics interfaces included in the model. To edit the

minput.T variable, click the

Go to Source button (

), and in the

Common Model Inputs node under

Global Definitions, set a value for the

Temperature in the

Expression for remaining selection section.

The Martensite volume fraction,

ξ, and the

Density of the alloy (defined for both Austenite and Martensite states) should be set in this section.

In addition, the following options are available for the computation of the Effective conductivity by accounting for both Austenite and Martensite properties:

The default Thermal conductivity kA is taken

From material. For

User defined select

Isotropic,

Diagonal,

Symmetric, or

Anisotropic based on the characteristics of the thermal conductivity, and enter another value or expression. For

Isotropic enter a scalar which will be used to define a diagonal tensor. For the other options, enter values or expressions into the editable fields of the tensor.

The default Heat capacity at constant pressure Cp,A is taken

From material. For

User defined enter a value or expression.

The default Thermal conductivity kM is taken

From material. For

User defined select

Isotropic,

Diagonal,

Symmetric, or

Anisotropic based on the characteristics of the thermal conductivity, and enter another value or expression. For

Isotropic enter a scalar which will be used to define a diagonal tensor. For the other options, enter values or expressions into the editable fields of the tensor.

The default Heat capacity at constant pressure Cp,M is taken

From material. For

User defined enter a value or expression.

If the Heat transfer in alloys check box is selected under the

Physical Model section:

More locations are available if the Heat transfer in alloys check box is selected under the

Physical Model section. For example:

Heat Transfer in Fluids>Shape Memory Alloy