|

•

|

|

•

|

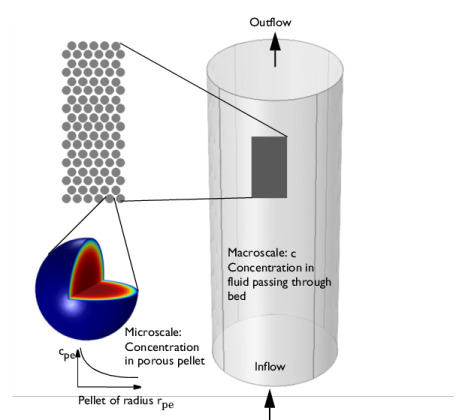

The dependent variable c for each chemical species i represents the interstitial concentration (SI unit: mol/m3), that is, the physical concentration based on unit volume of fluid flowing between the pellets.

|

|

•

|

εb is the bed porosity (SI unit: 1). It should be noted that the R term on the right hand side is per unit volume of bed, (SI unit: mol/(m3· s)).

|

|

•

|

N is the number of pellets per unit volume of bed.

|

|

•

|

Equally as in Equation 4-23, cpe is the interstitial (physical) species concentration in moles/m3 fluid volume element inside the pore channel,

|

|

•

|

Rpe is the reaction rate in moles/(m3· s) of particle volume. It should be stressed that the user input of R is per unit volume of pellet.

|

|

•

|

Continuous concentrations: assuming that all resistance to mass transfer is within the pellet and no resistance to pellet-fluid mass transfer on bulk fluid side. The concentration in the fluid will thus be equal to that in the pellet pore just at the pellet surface:

|

|

•

|

Film resistance (mass flux): The flux of mass across the pellet-fluid interface into the pellet is possibly rate determined on the bulk fluid side. The resistance is expressed in terms of a film mass transfer coefficient, hDi, such that:

|