In this case (see Figure 3-2), the device’s inlet is the interior face situated between the blue (cube) and green (circle) domains while its outlet is an external boundary, here the circular boundary of the green domain. The lumped curve gives the flow rate as a function of the pressure difference between the interior face and the external boundary. This boundary condition implementation follows the

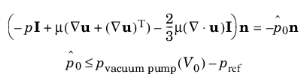

Pressure Boundary Condition for outlets with the Suppress backflow option:

Here, V0 is the flow rate across the boundary and

pvacuum pump(V0) is the static pressure function of flow rate for the vacuum pump.

pref is the reference pressure that ensure that the absolute pressure is set to

pvacuum pump. In vacuum pump models the reference pressure is usually set to 0 Pa since the absolute pressure is close to 0 Pa by opposition to ambient conditions where

pref is often set to 1 atm.

Equation 3-37 corresponds to the compressible formulation. For incompressible flows, the term

−(2/3)μ(∇ ⋅ u) vanishes. In 2D the thickness in the third direction,

Dz, is used to define the flow rate. Vacuum pumps are modeled as rectangles in this case.