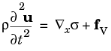

Here fV is a body force per unit deformed volume, and

ρ is the current mass density. For the material frame formulation used in COMSOL Multiphysics, it is more appropriate to use a Lagrangian version if the equation:

Now that the first Piola-Kirchhoff stress tensor, P, is used.

FV is a body force with components in the current configuration but given with respect to the undeformed volume, and

ρ0 is the initial mass density. Note the gradient operators are not the same: in the first case the gradient is taken with respect to the spatial coordinates, and in the second case with respect to the material coordinates. Using the more common second Piola-Kirchhoff stress tensor,

S, the same equation reads

where F is the deformation gradient. The COMSOL Multiphysics implementation of the equations in the Solid Mechanics interface is however not based on the equation of motion directly, but rather on the

principle of virtual work.

Damped eigenfrequencies can also be studied, so λ is not necessarily a purely imaginary number. Any damping included in the problem will automatically cause the eigenfrequencies to become complex valued.

In addition to the eigenfrequency, the quality factor, Q, and decay factor,

δ, for the model can be examined:

Here ε us the engineering strain,

εGL is the Green-Lagrange strain and

σ1 is the stress caused by the unit load. In terms of stiffness matrices, this corresponds to

where KL is the linear stiffness matrix, and

KNL is the nonlinear contribution to the full stiffness matrix. The symbolic linearization point

u0 is the displacement vector caused by the unit load.

By using the term (λ-1), the effect of using the Green-Lagrange strain tensor in the first term is to a large extent removed. Unless the unit load is significantly larger than the buckling load, the result will be the same as the intended, even if geometric nonlinearity was inadvertently selected in the eigenvalue study step.