This is an ellipse in p-q plane, with a cross section independent of Lode angle and smooth for differentiation. Note that

p,

q, and

pc are always positive variables.

The material parameter M > 0 defines the slope of a line in the

p-q space called

critical state line, and it can be related to the angle of internal friction

in the Mohr-Coulomb criterion

In the Cam-clay model, hardening is controlled by the consolidation pressure pc, which depends exponentially on the volumetric plastic strain

εpl,vol.

Here, the parameter pc0 is the initial consolidation pressure, and the exponent

Bpl is a parameter which depends on the initial void ratio

e0, the

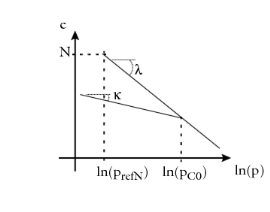

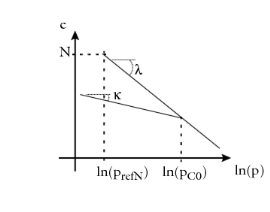

swelling index κ,

and the compression index λ:

In this formulation, the compression index λ is the slope of the

virgin isotropic consolidation line, and

κ is the slope of the

rebound-reloading line (also called loading-reloading line) in the

e versus

ln(p) plane.

Here, σ is the Cauchy stress tensor,

ε is the total strain tensor,

εinel is the inelastic strain tensor,

σ0 is the initial stress tensor, and

C is the fourth-order elasticity tensor.

here p0 =

− trace

(σ0)/

3 is the trace of the initial stress tensor

σ0, and

K is the bulk modulus, a constant parameter independent of the stress or strain.

and K0 a reference bulk modulus. This formulation gives a tangent bulk modulus

KT = −Bel(p−p0). The reference bulk modulus is calculated from the initial consolidation pressure

pc0, and the void ratio at reference pressure

N.

The associated flow rule (Qp =

Fy) and the yield surface written in terms of these two invariants,

Fy(

I1,

J2), gives a rate equation for the plastic strain tensor calculated from the derivatives of

Fy with respect to the stress tensor

σ

This relation explains the reason why there is isotropic hardening for

p > pc/2 and

isotropic softening for

p < pc/2. So the volumetric plastic strain can either increase or decrease.

When a pore fluid pressure pf is added to the Cam-clay material, the yield surface is shifted on the

p axis

The quantity p − pf is normally regarded as the

effective pressure, or effective stress, which should not be confused with von Mises stress.