The Bresler-Pister criterion (Ref. 2) was originally devised to predict the strength of concrete under multiaxial stresses. This failure criterion is an extension of the Drucker-Prager criterion to brittle materials and can be expressed in terms of the stress invariants as

This criterion can also be written (Ref. 17) in term of the uniaxial compressive strength

fc and the octahedral normal and shear stresses

Here, the parameters a,

b, and

c are obtained from the uniaxial compression, uniaxial tension, and biaxial compression tests, respectively. The octahedral normal stress

σoct is considered positive when tensile, and

fc is taken positive.

The Willam-Warnke criterion (Ref. 10) is used to predict failure in concrete and other cohesive-frictional materials such as rock, soil, and ceramics. Just as the Bresler-Pister criterion, it depends only on three parameters. It was developed to describe initial concrete failure under triaxial conditions. The failure surface is convex, continuously differentiable, and is fitted to test data in the low compression range. The material is considered perfect elastoplastic (no hardening).

where fc is the uniaxial compressive strength,

ft is uniaxial tensile strength, and

fb is obtained from the biaxial compression test. All parameters are positive. The octahedral normal and shear stresses are defined as usual

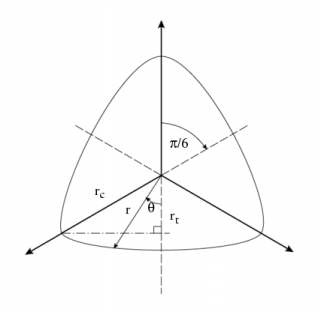

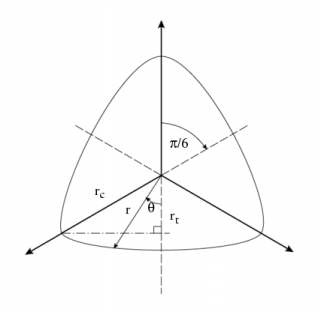

The function r(

θ) describes the segment of an ellipse on the octahedral plane when

. By using the Lode angle

θ, the dimensionless function

r(

θ) is defined as

Here, the tensile and compressive meridian rt and

rc are defined in terms of the positive parameters

fc,

fb, and

ft:

The function r(

θ) can be interpreted as the friction angle which depends on the Lode angle (

Ref. 10).

In this formulation, the parameters a>0,

b>0,

k1>0, and

k2>0 are dimensionless, and

fc>0 is the uniaxial compressive strength of concrete (with a positive sign). The function

(dimensionless) is defined as

The parameter k1 is called the

size factor. The parameter

k2 (also called

shape factor) is positive and bounded to 0

≤ k2 ≤ 1(

Ref. 17,

Ref. 18).

Typical values for these parameters are obtained by curve-fitting the uniaxial compressive strength fc, uniaxial tensile strength

ft, and from the biaxial and triaxial data (for instance, a typical biaxial compressive strength of concrete is 16% higher than the uniaxial compressive strength). The parameters

fc,

fb, and

ft are positive.

where σ1 ≥ σ2 ≥ σ3 ≥ 0 are the principal stresses at failure (as defined in geotechnical engineering; that is, an

absolute value),

σc is the uniaxial compressive strength of the intact rock (positive parameter), and

m and

s are positive material parameters.

with σc,

m, and

s positive material parameters. (In this case, note that

σ1 < sσc/m).

As developed originally, there is no relation between the parameters m and

s and the physical characteristics of a rock mass measured in laboratory tests. However, for intact rock,

s = 1 and

m = mi, which is measured in a triaxial test.

For jointed rock masses, 0 ≤ s

< 1 and

m < mi. The parameter

m usually lies in the range

5 < m < 30 (

Ref. 7).

The generalized Hoek-Brown criterion was developed in order to fit the Geological Strength Index (GSI) classification of isotropic rock masses (Ref. 6). A new relationship between GSI,

m,

s and the newly introduced parameter

a was developed, to give a smoother transition between very poor quality rock masses (GSI

<

25) and stronger rocks

where σ1 ≥ σ2 ≥ σ3 are the principal stresses (using the Structural Mechanics Module conventions) of the

effective stress tensor (this is, the stress tensor minus the fluid pore pressure).

The positive parameter mb is a reduced value of the material constant

mi:

s and

a are positive parameters for the rock mass given by the following relationships:

The disturbance factor D was introduced to account for the effects of stress relaxation and blast damage, and it varies from

0 for undisturbed in-situ rock masses to

1 for very damaged rock masses.