Viscoelastic materials have a time-dependent response even if the loading is constant in time. Many polymers and biological tissues exhibit this behavior.

Linear viscoelasticity is a commonly used approximation where the stress depends linearly on the strain and its time derivatives (strain rate). Also, linear viscoelasticity deals with the

additive decomposition of stresses and strains. It is usually assumed that the viscous part of the deformation is incompressible so that the volumetric deformation is purely elastic.

where the elastic strain tensor εel = ε − εinel represents the total strain minus initial and inelastic strains, such as thermal strains.

The elastic strain tensor εel can in the same way be decomposed into volumetric and deviatoric components

In case of geometric nonlinearity, σ represents the second Piola-Kirchhoff stress tensor and

εel the elastic Green-Lagrange strain tensor.

For viscoelastic materials, the deviatoric stress σd is not linearly related to the deviatoric strain

εd but it also depends on the strain history. It is normally defined by the hereditary integral:

The function Γ(

t) is called the

relaxation shear modulus function (or just

relaxation function) and it can be found by measuring the stress evolution in time when the material is held at a constant strain.

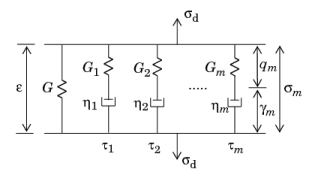

Hence, G is the stiffness of the main elastic branch,

Gm represents the stiffness of the spring in branch

m, and

τm is the

relaxation time constant of the spring-dashpot pair in branch

m.

The auxiliary strain variable qm is introduced to represent the extension of the corresponding abstract spring, and the auxiliary variables

γm = ε − qm represent the extensions in the dashpots.

The shear modulus of the elastic branch G is normally called the

long-term shear modulus, or

steady-state stiffness, and is often denoted with the symbol

. The instantaneous shear modulus

G0 is defined as the sum of the stiffness of all the branches

The relaxations time τm is normally measured in the frequency domain, so the viscosity of the dashpot is not a physical quantity but instead it is derived from stiffness and relaxation time measurements. The viscosity of each branch can be expressed in terms of the shear modulus and relaxation time as

The total stress in Hooke’s law (Equation 3-11) is then augmented by the viscoelastic stress

σq

The auxiliary variable γm is a symmetric strain tensor, which has as many components as the number of strain components of the problem class. Since the stress per branch is written as

the auxiliary variables γm can be computed by solving the ODE

so that Equation 3-16 can equivalently be written as

The viscoelastic strain variables γm are treated as additional degrees of freedom. The shape functions are chosen to be one order lower than those used for the displacements because these variables add to the strains and stresses computed from displacement derivatives. The viscoelastic strain variables do not require continuity so discontinuous shape functions are used.

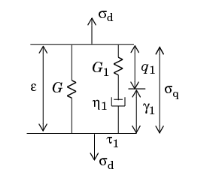

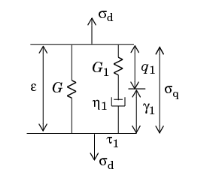

The standard linear solid model, also called

SLS model,

Zener model, or

three-parameter model, is a simplification of the generalized Maxwell model with only one spring-dashpot branch:

The auxiliary strain tensor γ1 is computed after solving by the ODE

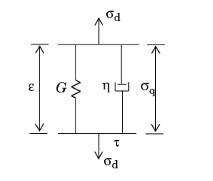

The Kelvin–Voigt viscoelastic model is represented by a spring connected in parallel with a damper:

For many polymers, the viscoelastic properties have a strong dependence on the temperature. A common assumption is that the material is thermorheologically simple (

TRS). In a material of this class, a change in the temperature can be transformed directly into a change in the time scale. The reduced time is defined as

where αT(

T) is a temperature-dependent shift function.

Think of the shift function αT(

T) as a multiplier to the viscosity in the dashpot in the Generalized Maxwell model. This shifts the relaxation time, so

Equation 3-17 for a TRS material is modified to

The first step to compute the shift factor αT consists of building a

master curve based on experimental data. To do this, the curves of the viscoelastic properties (shear modulus, Young’s modulus, and so forth.) versus time or frequency are measured at a reference temperature

T0. Then, the same properties are measured at different temperatures.

The shift value of each curve with respect to the master curve obtained at the temperature T0 defines the shift factor

αT(

T). The constants

C1 and

C2 are material dependent and are calculated after plotting

log(

αT) versus

T − T0.

Since the master curve is measured at an arbitrary reference temperature T0, the shift factor

αT(

T) can be derived with respect to any temperature, and it is commonly taken as the shift with respect to the glass transition temperature. The values

C1 =

17.4 and

C2 =

51.6 K are reasonable approximations for many polymers at this reference temperature.

Below the Vicat softening temperature, the shift factor in polymers is normally assumed to follow an Arrhenius law. In this case, the shift factor is given by the equation

here, a base-e logarithm is assumed, Q is the activation energy (SI unit: : J/mol), and

R is the universal gas constant.

The instantaneous shear modulus G0 is defined as the sum of the stiffness of all the branches

where the shear storage modulus G’ and the

shear loss modulus G” are defined for the generalized Maxwell model as