|

|

1

|

|

2

|

In the Select Physics tree, select Heat Transfer>Radiation>Heat Transfer with Surface-to-Surface Radiation (ht).

|

|

3

|

Click Add.

|

|

4

|

Click Study.

|

|

5

|

|

6

|

Click Done.

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

Click to expand the Layers section. In the table, enter the following settings:

|

|

5

|

|

1

|

|

2

|

On the object c1, select Boundaries 1–12 only.

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

On the object uni1, select Points 1, 4, 5, and 8–10 only.

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

Click to expand the Layers section. In the table, enter the following settings:

|

|

7

|

|

1

|

|

2

|

|

3

|

|

4

|

On the object c2, select Domain 1 only.

|

|

1

|

|

2

|

|

3

|

|

4

|

Click Range.

|

|

5

|

|

6

|

|

7

|

|

8

|

Click Replace.

|

|

9

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Click OK.

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

4

|

|

1

|

|

2

|

|

3

|

In the tree, select Built-In>Air.

|

|

4

|

|

1

|

|

3

|

|

1

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Locate the Surface Emissivity section. From the ε list, choose User defined. In the associated text field, type 0.01.

|

|

1

|

|

3

|

|

4

|

|

5

|

|

1

|

|

3

|

|

4

|

|

5

|

Locate the Surface Emissivity section. From the ε list, choose User defined. In the associated text field, type 0.1.

|

|

1

|

|

3

|

|

4

|

|

5

|

Locate the Surface Emissivity section. From the ε list, choose User defined. In the associated text field, type 0.1.

|

|

1

|

|

3

|

|

4

|

|

1

|

|

3

|

|

4

|

|

5

|

Locate the Surface Emissivity section. From the ε list, choose User defined. In the associated text field, type 0.99.

|

|

1

|

|

3

|

|

4

|

|

1

|

|

3

|

|

4

|

|

5

|

Locate the Surface Emissivity section. From the ε list, choose User defined. In the associated text field, type 0.99.

|

|

1

|

|

3

|

|

4

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

In the Model Builder window, under Component 1 (comp1)>Mesh 1 right-click Free Triangular 1 and choose Size.

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

9

|

|

10

|

|

1

|

|

2

|

|

3

|

|

1

|

In the Model Builder window, under Component 1 (comp1)>Mesh 1 right-click Free Triangular 1 and choose Size.

|

|

2

|

|

3

|

|

5

|

|

6

|

|

7

|

|

8

|

|

9

|

|

10

|

|

1

|

|

2

|

|

3

|

Click Add.

|

|

4

|

Click Range.

|

|

5

|

|

6

|

|

7

|

|

8

|

Click Replace.

|

|

9

|

|

1

|

|

2

|

|

3

|

In the Model Builder window, expand the Study 1>Solver Configurations>Solution 1 (sol1)>Stationary Solver 1 node, then click Parametric 1.

|

|

4

|

|

5

|

|

6

|

|

1

|

|

1

|

|

2

|

|

3

|

|

1

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

3

|

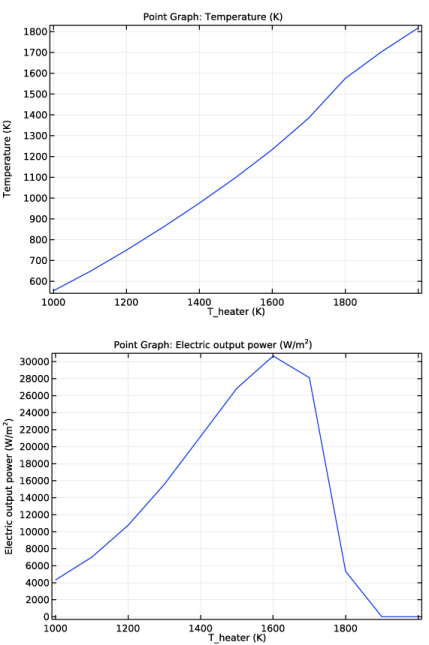

In the Settings window for Point Graph, click Replace Expression in the upper-right corner of the y-axis data section. From the menu, choose Model>Component 1>Definitions>Variables>q_out - Electric output power.

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

3

|

In the Settings window for Line Graph, click Replace Expression in the upper-right corner of the y-axis data section. From the menu, choose Model>Component 1>Heat Transfer with Surface-to-Surface Radiation>Radiation>Mutual surface irradiation>ht.Gm_gp - Mutual surface irradiation, Gauss point evaluation.

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|