|

|

1

|

|

2

|

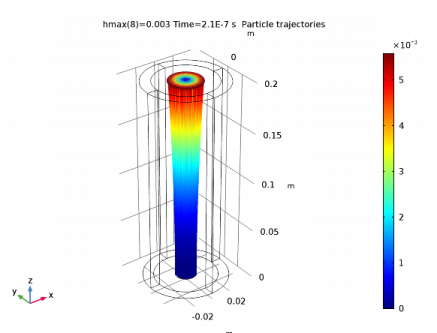

Compute the electric potential due to the space charge density of the beam, using a stationary solver. The model uses an Infinite Element Domain region to apply appropriate boundary conditions for a beam propagating in free space.

|

|

1

|

|

2

|

In the Select Physics tree, select AC/DC>Particle Tracing>Particle Field Interaction, Non-Relativistic.

|

|

3

|

Click Add.

|

|

4

|

Click Study.

|

|

5

|

In the Select Study tree, select Preset Studies for Selected Physics Interfaces>Bidirectionally Coupled Particle Tracing.

|

|

6

|

Click Done.

|

|

1

|

|

2

|

|

3

|

|

4

|

Browse to the model’s Application Libraries folder and double-click the file electron_beam_divergence_parameters.txt.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Click to expand the Layers section. In the table, enter the following settings:

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

On the object cyl1, select Boundary 10 only.

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

In the Model Builder window, under Component 1 (comp1) right-click Materials and choose Blank Material.

|

|

2

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

1

|

In the Model Builder window, under Component 1 (comp1) right-click Charged Particle Tracing (cpt) and choose Inlet.

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

In the Model Builder window, under Component 1 (comp1)>Charged Particle Tracing (cpt) click Electric Force 1.

|

|

3

|

|

4

|

|

5

|

Locate the Advanced Settings section. Select the Use piecewise polynomial recovery on field check box.

|

|

1

|

In the Model Builder window, under Component 1 (comp1) right-click Electrostatics (es) and choose Ground.

|

|

1

|

In the Model Builder window, under Component 1 (comp1) right-click Mesh 1 and choose Free Tetrahedral.

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

Click the Custom button.

|

|

4

|

|

1

|

|

2

|

|

3

|

|

1

|

In the Settings window for Bidirectionally Coupled Particle Tracing, locate the Study Settings section.

|

|

2

|

Click Range.

|

|

3

|

|

4

|

|

5

|

Click Replace.

|

|

6

|

|

7

|

|

8

|

|

9

|

|

10

|

|

11

|

|

1

|

|

2

|

|

3

|

Click Add.

|

|

5

|

Click Range.

|

|

6

|

|

7

|

|

8

|

|

9

|

Click Replace.

|

|

10

|

|

1

|

In the Model Builder window, expand the Results>Particle Trajectories (cpt) node, then click Particle Trajectories 1.

|

|

2

|

|

3

|

|

1

|

In the Model Builder window, expand the Particle Trajectories 1 node, then click Color Expression 1.

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

In the Settings window for Global, type Relative Error in Longitudinal Beam Displacement in the Label text field.

|

|

3

|

|

4

|